Dry adhesion-based shape memory polymer (SMP) gripper with high-load capacity and a high adhesion switching ratio.

Problem:

Robotic arms that aim to grip and manipulate objects require grippers that can conform to flat and 3D objects while sustaining large loads. Friction-based robotic grippers can pick up 3D objects but merely flat objects and small objects. Furthermore, other adhesion-based grippers can only pick flat objects but not 3D objects. Even though there exist additional adhesion gripper designs that can grip 3D objects, their load capacity and/or adhesion switchability are not high enough.

Solution:

A dry adhesion-based gripper with a high adhesive load capacity that exploits an unstructured shape memory polymer (SMP) membrane with tunable stiffness, enabling rapid gripping and releasing of 3D objects. SMPs are known to be polymeric smart materials that have the ability to return from a deformed state to their original shape when triggered by an external stimulus. The stiffness of the shape memory polymer is managed by temperature control, wherein heating enables it to conform to an object’s shape while cooling stiffens the material and enables high load capacity.

Technology:

The inventors demonstrate a shape memory polymer (SMP)-based adhesive gripper with variable stiffness to pick and place 3D objects. Shape memory polymers (SMPs) are materials that can remember their original shape, stay in temporarily deformed shapes, and return to the original shape by an external stimulus, which makes them particularly useful in applications where flexibility and adaptability are important. The gripper is fabricated with an unstructured flat thermally responsive SMP membrane composed of two-part epoxy (EPON826 resin and Jeffamine D230 (poly (propylene glycol) bis (2-aminopropyl) ether curing agent. The SMP is connected to a flexible heater and a thermocouple attached to a heater used for measurement and control of the temperature.

When the SMP is in a soft state, it is flexible and can conform to the shape of the object being picked up. This allows the gripper to make good contact with the object, which is important for achieving a strong adhesive bond. The soft state of the SMP also allows the gripper to conform to objects with irregular shapes or surfaces that might be difficult to pick up with a rigid gripper. Due to the variable stiffness of SMPs, once the SMP-based adhesive gripper has contacted the object, it can switch to a stiff state, which increases the adhesive load capacity of the gripper. This allows the gripper to hold the object securely, even if it is of a high load or has an irregular shape.

Advantages:

- The SMP membrane is comprised of a material with low modulus in the soft state, as well as a membrane geometry with low axial and negligible bending stiffness, which makes it highly effective at adapting and conforming to nonplanar and deformable objects

- Unstructured flat variable stiffness SMP membrane requires no microfabrication and can be manufactured via a simple casting process

- Unstructured flat variable stiffness SMP membrane enables the gripper to achieve a high load capacity and a high adhesion switching ratio, in comparison to gripper based on elastomer membranes

- SMP membrane exhibits no adhesion at rest, which prevents any unintended adhesion

- Once the SMP membrane encounters an object and stiffens, it can passively maintain a high adhesion state without requiring continuous actuation. Soft robotic gripper offers better conformability and reduces the risk of object damage.

- Adhesion-based grippers can provide gripping forces that act both tangential and normal to a surface

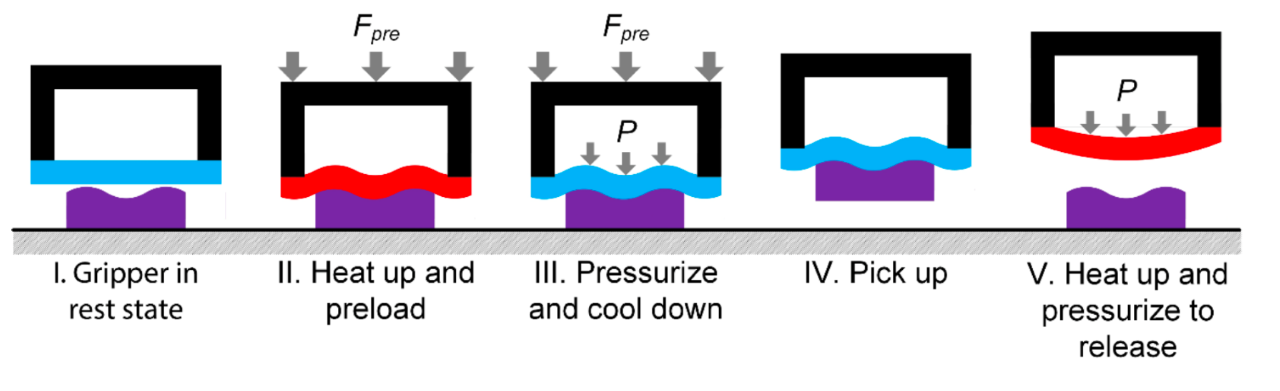

The figure depicts the principle of operation of the SMP adhesive gripper. When not heated, the SMP membrane is stiff and cannot easily make conformal contact with other surfaces. During use, the SMP membrane is heated to 70 oC to soften the SMP, then the membrane is contacted with the object. The contact forms by displacing the chamber supporting the SMP membrane to bring the membrane in contact with the object. While maintaining contact, the SMP membrane is cooled to 30 oC. On cooling and stiffening, higher load capacity is achieved, allowing the gripping of various objects and shapes. Objects are released through the heating and softening of the SMP membrane.

Case ID:

22-9909-tpNCS

Web Published:

7/19/2023

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |