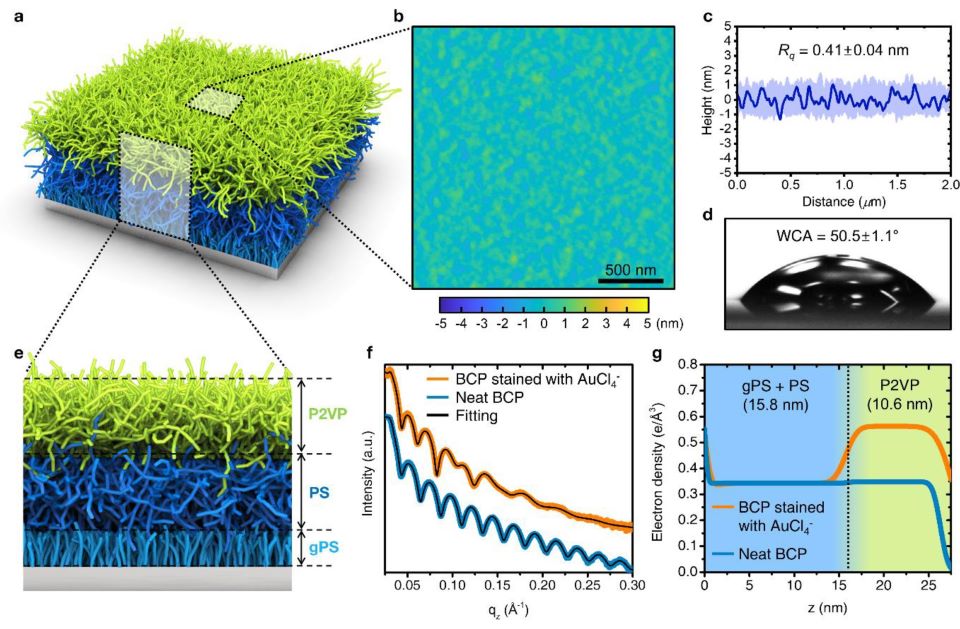

A polymer brush coating on a substrate made through block copolymer coating and exfoliation for pH-mediated nanoparticle sorting, transport, and diffusion.

Problem:

NP-based technologies in fields such as biotherapeutics, separation, and purification require precise control of nanoparticle transport, absorption, and diffusion. Polymer brushes exhibit an effective stimuli-response surface for controlling the interaction with nanoparticles, with potential stimuli including the solution pH or external electric field. Existing methods of polymer brush preparation methods make use of complex chemical synthesis for brush fabrication. These techniques covalently bond polymer brushes using “grafting-from” or “grafting-to” methods on the substrate. These methods can be time consuming (e.g., growing a polymer brush from the surface), narrowly applicable, energy intensive, and expensive.

Solution:

A fabrication method that uses selective exfoliation of a block copolymer coating to expose brush material, avoiding work-intensive chemical grafting approaches. The brush swells and stretches in response to pH stimulus, allowing for selective adsorption of nanoparticles.

Technology:

A grafted polystyrene (gPS) layer is fabricated on an oxide substrate (e.g., SiO2) using an ω-hydroxy-terminated polystyrene (PS), resulting in a smooth, hydrophobic surface. Over this “primer” layer, a block copolymer coating, containing PS-block-poly (2-vinyl pyridine) (P2VP) layers, is thermally annealed on the gPS, forming a parallel lamellar bilayer with PS domains on top due to the high surface energy of P2VP. To invert the structure and obtain an outer P2VP domain, methanol is used in conjunction with sonication to selectively penetrate and dissolve the P2VP domain, removing the outermost PS-block-P2VP coating and exposing the P2VP outer domain. The P2VP domain, anchored to the gPS via the glassy PS domain, can stretch and swell in response to pH, allowing pH-mediated gold nanoparticle adsorption by controlling the permeability depending on the size of the nanoparticles.

Advantages:

- Simple, robust exfoliation fabrication method that avoids the complex chemical grafting processes used for traditional polymer brushes

- Tunable adsorption of nanoparticles with pH-dependent size selectivity, allowing for nanoparticle sorting, rather than just transport and diffusion applications

- Brushes can release nanoparticles back into solution, allowing for reusability

(a) Schematic illustration of P2VP brush on a Si wafer (blue is PS and green is P2VP). (b) AFM height image (512-by-512 pixels). (c) Height profiles collected from every pixel row (total 512 rows) shown in light blue. A representative height profile shown in blue. (d) Photo of a water droplet on the P2VP brush. (e) A schematic of the side view of the BCP monolayer. (f) X-ray reflectivity profiles and (g) the electron density profile along the z-axis of a neat BCP monolayer and after incorporation of AuCl4- ions in the protonated P2VP brush. A dashed line indicates the position of the junction between the PS and P2VP blocks.

Stage of Development:

- Proof of Concept

- Bench Prototype

Case ID:

23-10260-tpNCS

Web Published:

10/3/2023

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |