Employment of omniphobic, thin-layer perfluorocarbon (TLP) coating to prevent fouling and clogging in microfluidic mixing devices during mRNA LNP formulations.

Problem:

Lipid nanoparticle (LNP)-based delivery systems for mRNA and other therapeutics recently gained popularity because of their application in the Pfizer/BioNTech and Moderna COVID-19 vaccines. Compared to traditional bulk mixing and batch process approaches, microfluidic technology for mRNA-LNP manufacturing enables precision synthesis via rapid mixing and fluid flow control. However, fouling and clogging in microfluidic channels pose significant problems for LNP formulation as numerous existing hydrophilic/hydrophobic coatings only inhibit biomolecule adsorption and fouling in aqueous solutions, while the condition for LNP formation is a mixture of hydrophilic aqueous and amphiphilic ethanol (EtOH) solvents.

Solution:

Coating a silicon (Si)/glass-based microfluidic mixing device with omniphobic, thin-layer perfluorocarbon (TLP) improves chemical resistance, suppresses non-specific biomolecule adsorption, and prevents nanoparticle aggregation.

Technology:

The TLP layer consists of an immobilized tethered perfluorocarbon (TP) overlaid by a thin liquid perfluorocarbon (LP) layer, which is an FDA-approved material. Application of TLP coating to a Si/glass microfluidic mixing device repels water, EtOH, and water/EtOH mixture while suppressing non-specific adsorption of biomolecules such as BSA, glycine, and mRNA-LNP constituents. This prevents fouling of mRNA and LNP constituents.

Advantages:

- An antifouling resistant GMP compatible manufacturing platform using FDA-approved material.

- High-precision mRNA-LNP production (size < 100 nm, encapsulation efficiency > 90%).

- Robust mRNA-LNP production (operation t > 50 min without clogging).

- Prevents aggregation of nanoparticles, which expands its application to other nanomaterials and devices lined by anti-adsorption and antifouling surfaces.

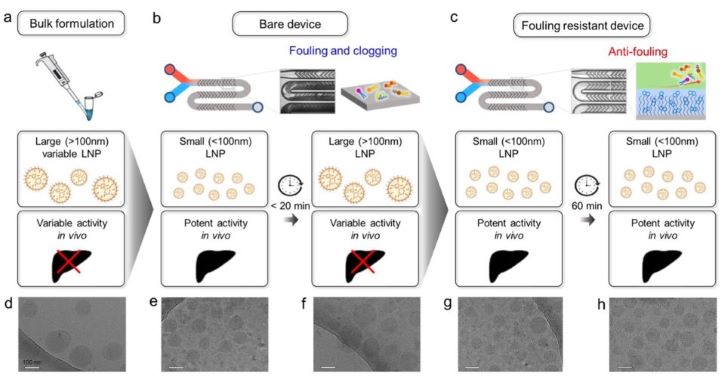

Schematic for robust mRNA-LNP formulation using fouling-resistant microfluidic mixing device. Compared to (a) the conventional bulk formulation method and (b) bare microfluidic mixing device that produce large and more heterogeneous LNPs with variable RNA delivery, (c) the fouling-resistant microfluidic device produces smaller, more homogeneous LNPs with potent in-vivo RNA delivery and activity. It also extends the operation to over 50 minutes without clogging. (d-h) Cryo-EM images of LNPs produced with bulk formulation, bare device, and fouling-resistant device, respectively.

Stage of Development:

- Proof of Concept

- Bench Prototype

Reference Media:

- Kim, B. Q. et al., Nano Small, 2023 Sept 27; Vol.19(39): e2302676

- Shepherd, S. J. et al., Proc Natl Acad Sci USA, 2023 Aug 15; 120(33): e2303567120

- Tran, H.-H. et al., Rep. Prog. Phys., 2023 May 22; Vol. 86(6): 066601

- Rose, K.A. et al., Soft Matter, 2022 Dec 7; Vol. 18(47): 9045

- Wu, J. et al., Applied Phys. Reviews, 2021 July 19; Vol. 8(3): 031304

- Shepherd, S. J. et al., Science Direct, Biomaterials, 2021 Apr. 26; Vol. 274: 120826

Case ID:

23-10440-tpNCS

Web Published:

7/15/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |