Method to transfer wettability properties of a mold to microfluidic devices, defining hydrophobic/hydrophilic regions through variable perfluoropolyether concentration.

Problem:

Current wettability patterning methods involve sequentially flowing chemicals into channels, blocking areas where treatment is not desired. These multi-step methods are labor intensive and have limited spatial resolution. Additionally, the scalability of these processes is not feasible, as each device must be patterned individually. These processes are additive and generate surfaces that are not flat, limiting the available topographies of these microfluidic devices.

Solution:

A technique that patterns a mold, which then transfers its wettability properties to the microfluidic device, allowing for single-step generation of hydrophobic/hydrophilic regions. The mold is reusable, allowing for mass-production of microfluidic channels. This process is less time-consuming and labor-intensive compared to traditional wettability patterning, and is not additive, so smooth surfaces can be generated.

Technology:

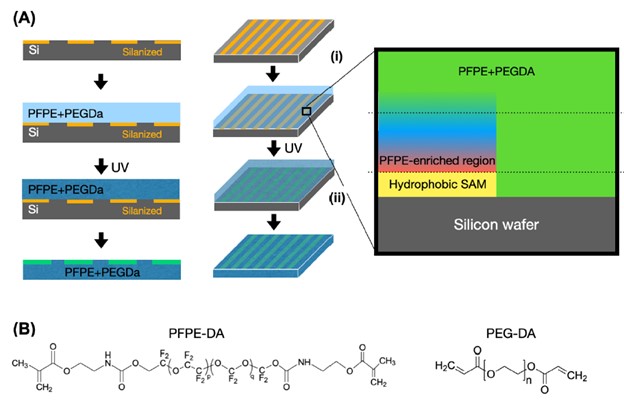

This method allows selective hydrophobic perfluoropolyether (PFPE) enrichment in regions, rather than uniform distribution, by patterning a silica mold substrate with hydrophobic silane-treated regions. The wettability of the mold is then transferred to the network surface as areas adjacent to the silane-treated regions become PFPE-enriched and thus hydrophobic, while the unenriched regions remain relatively hydrophilic. The polymer network is then cured with UV light, peeled off the mold, and dried to form the channel.

Advantages:

- Single-step definition of hydrophobic/hydrophilic regions allows for faster fabrication of microfluidic devices compared to multi-step treatment with individual hydrophobic/hydrophilic components.

- The method is compatible with traditional soft lithography techniques.

- The use of a reusable mold that transfers wettability allows for faster fabrication and more facile scalability, as each device does not need to be individually patterned.

- The resulting microfluidic devices are solvent resistant.

- The process is non-additive, allowing for generation of smooth surfaces, which is not possible for traditional wettability patterning.

- Micrometer-level spatial resolution compares favorably to the resolution afforded by multi-step techniques.

(A) Scheme for generating and curing hydrophilic/hydrophobic networks with silanized patterning used to dictate wettability. (B) Chemical structures of hydrophobic PFPE and hydrophilic PEGDA polymers.

Stage of Development:

- Proof of Concept

- Bench Prototype

Case ID:

22-10109-TpNCS

Web Published:

7/22/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |