An origami-based approach to generate complex shapes by folding magnetically programmed sheets.

Problem:

Shape-changing materials are desirable in applications such as soft robotics, implantable and wearable devices, minimally invasive medicine, and micromachines. Common control signals used for self-folding, such as temperature, diffusion, and capillary forces, often require long wait times for the signal to dissipate, making repeated folding and unfolding challenging. Faster methods using chemical, electrochemical, or light signals are difficult to reprogram into different structures. Systems using active computation and directed actuation for folding control can generate different shapes over multiple folding steps, enabling the formation of different 3D shapes from the same material. However, these systems are not scalable.

Solution:

Magnetic actuation offers a simple option for fast, reprogrammable shape change simply by applying an external magnetic field to a precisely-oriented magnetized sample.

Technology:

The Sung Lab developed a fully automated approach for manufacturing self-assembling, self-reconfiguring, and reprogrammable structures. Like the magnetic writing commonly used in hard disk drive perpendicular recording, this approach uses a magnetic write head that programs a thin magnetic sheet with North or South signals at the pixel level. Previous magnetic folding systems (for example, direct ink, lithography-based, bottom-up assembly-based) relied on fabricating the fold pattern directly into the sheet, making the reconfiguration difficult without human input. However, the system presented here is fully automated after inserting the programmable sheet.

Advantages:

- The system provides distinct advantages compared to existing magnetic folding approaches in its ability to accommodate any flat-foldable pattern.

- The system enables simultaneous programming and mass production of custom-folded structures.

- The obtained structures are recyclable and reprogrammable.

- Adding different components (such as electronics for control, sensing, or feedback) to the programmable sheets is possible.

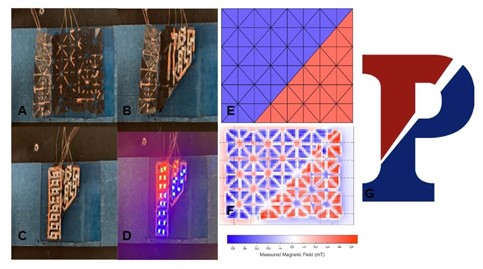

Foldable electronic display. (A) The unfolded display has LEDs on each face. (B) To fold into a “P,” the first step is to fold the bottom left corner. (C) The second step is to fold the left side. (D) When the display is on, the LEDs light up into a red and blue pattern. (E) Magnetic program used to generate the required folding sequence. (F) Magnetic image of the program on the fabricated sheet. (G) Reference Penn logo used for the display.

Intellectual Property:

- Provisional Patent Application Filed

Case ID:

23-10185-TpNCS

Web Published:

8/14/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |