The formulation replaces up to 50 weight percent of ordinary Portland cement (OPC) with the highly porous, biomineral, diatomaceous earth.

Problem:

Concrete is the world’s second-most-used material, and its production process is carbon-intensive, contributing significantly to greenhouse gas emissions. One promising solution is carbon capture and storage within the concrete, with extensive research on mixing processes, carbonation curing of cast concrete, and recycling waste aggregates. However, some challenges remain unaddressed, including relatively slow carbonation kinetics and difficulties ensuring uniform carbonation in large or thick concrete structures. To achieve net-zero carbon emission goal, simply by absorbing CO2 in concrete is not enough.

Solution:

This invention is a 3D-printable concrete formulation derived from naturally abundant materials. It incorporates hierarchical porous biominerals, which significantly reduce mineral waste, carbon footprint, and enhance the concrete's carbon absorption and storage capacity.

Technology:

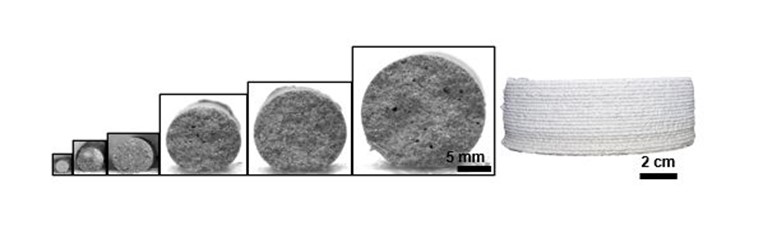

Supplementary cementing materials (SCMs) can reduce the use of cement while providing carbon capture and storage capabilities. The inventors replace up to 50 wt.% of ordinary Portland cement (OPC) with a natural SCM, diatomaceous earth (DE), which improves the material’s printability and the structural integrity of the prints. The pores of DE store water, which mitigate drying-induced shrinkage and thus fractures in the printed layers. The negative charge of DE can bind calcium ions and form calcium carbonate, further strengthening the concrete and enabling continuous carbon capture and storage.

Advantages:

- Reducing greenhouse gas emissions

- The porosity of diatomaceous earth offers the concrete formulation with buildability, 3D printability, and strength mandated for conventional concrete

- The concrete formulation replaces up to 50 wt.% of ordinary Portland cement with DE, contributing to reduced material waste and improved sustainability

- Stable stacking of up to 111 print layers (200 mm) compared to the version without DE (51 layers, 98.6 mm)

- The concrete efficiently absorbs 145% more CO2 than concrete without DE

Left: Concrete mixture from diatomaceous earth (DE)/Cement = 0.3 weight ratio extruded through 2 mm nozzle. Right: Scanning electron microscopy (SEM) images of the pores in the structure of DE at different magnification.

Case ID:

24-10625-TpNCS

Web Published:

8/23/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |