A printing system with a single nozzle/printhead that can dispense multiple materials in a controlled manner.

Problem:

Multi-material additive manufacturing transcends the limitations of traditional manufacturing processes by allowing the fabrication of complex, functionally graded components with tailored material properties. However, limitations remain in its adoption and scalability. Many existing 3D printers have multiple nozzles that require the swapping in and out of filament material during material processing. The trending slicing software lacks the ability to incorporate differentiated material information and merge it into machine instruction programs, and the material transition process critical for producing high quality prints has received little investigation. These limitations result in downtime and inconsistent material parameters.

Solution:

An integrated single-nozzle multi-filament (SNMF) system with hardware, software and firmware design eliminates the need for material swap-out during printing and allows for controlled gradient compositions and transitions.

Technology:

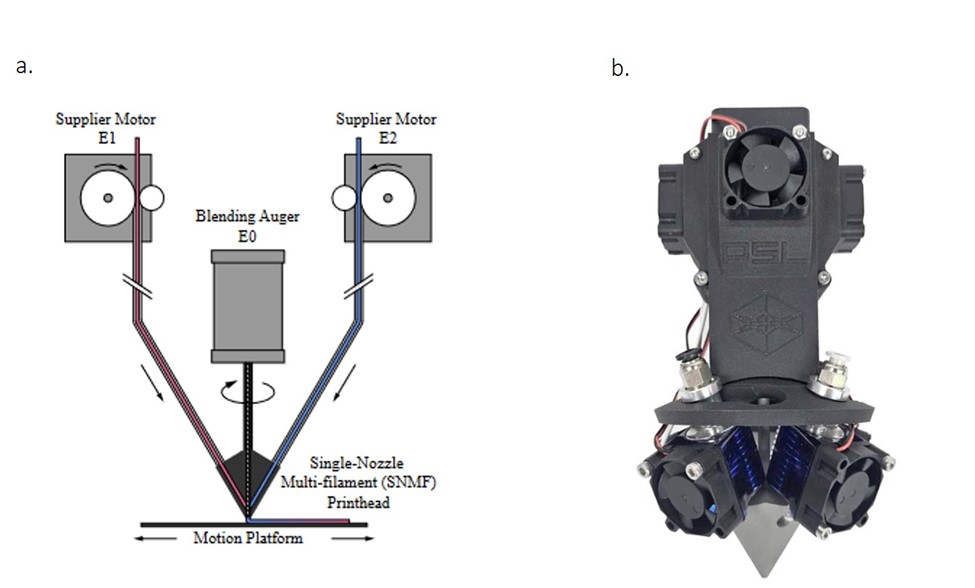

The SNMF printing system, rooted in the fused deposition modeling (FDM) technique, consists of three primary components: a single 4-in-1-out (four input chambers that merge at the center and subsequently connect to one output chamber) nozzle for depositing material, an auger embedded in the nozzle for extruding and blending materials, and a set of stepper motors for feeding different materials. In addition to hardware that is compatible with multiple thermoplastic filaments, the slicing software embeds differentiated material information, and the firmware enables material composition control with intricate motor regulation.

Advantages:

- Permits a seamless transition between materials without the need for material swap out during production, allowing for printing without stopping

- Can extrude and blend multiple filaments with precise control, enabling higher material continuity, graded material transitions and programmable compositions

- Can create complex 2D patterns and 3D structures

- May be used for macro-scale productions

Depiction of the single-nozzle multi-filament (SNMF) printing system. a) The proposed SNMF printer with a nozzle for depositing material, a blending auger embedded in the nozzle, and a set of stepper motors for feeding varied materials. b) The 4-in-1-out printhead prototype.

Intellectual Property:

- U.S. Provisional Patent Application Filed

Case ID:

24-10644-TpNCS

Web Published:

8/23/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |