A microfluidic device allowing spatiotemporal manipulation of droplets that can be applied to high-resolution analytical techniques.

Problem:

Electrowetting methods such as electrowetting-on-dielectric (EWOD) have been developed to support high-resolution analytical techniques such as mass spectrometry and atomic force microscopy. EWOD allows processing of liquid droplets on solid surfaces or within a thin space. However, the applicability of EWOD is limited by the contact between the droplet and the electrode, which limits droplet size. While other contactless wetting technologies have been developed, they perform poorly in modifying contact angle of the droplet. In addition, microfluidic devices that allow recovery of deposited materials from solid surfaces can benefit subsequent analysis or tagging of individual droplets.

Solution:

The inventors developed a contactless method to induce reversible droplet wetting and dewetting on chemically inert substrates, employing the technology of discharge-based dielectric charge injection (DCI). This method allows larger droplet size without sacrificing the ability to modify contact angle of the droplet.

Technology:

DCI uses a sharp conductive probe placed above the droplet that induces dielectric breakdown of the surrounding dielectric medium (e.g., air or oil), leading to corona discharge, a phenomenon where the dielectric ionizes and injects charges onto the substrate surface. The substrate surface in DCI shares a similar design to that of EWOD, where a thin dielectric film is deposited above an electrode. The system demonstrates voltage-dependent contact angle saturation, with a prototype reaching the lowest contact angle of about 20°. As a reversible system, complete dewetting is achieved by turning off the power source, which leads to charge dissipation.

Advantages:

- Simple design

- Contactless, allowing flexibility in droplet size

- Reversible, allowing material deposition and recovery

- Small contact angle that is competitive with traditional EWOD

- Spatiotemporally controlled

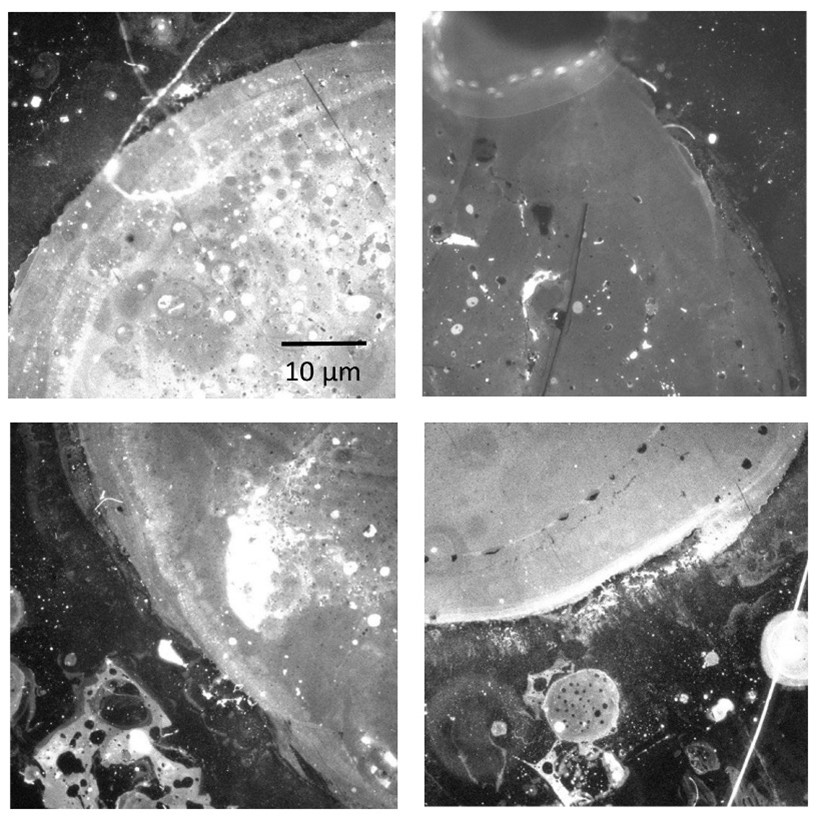

Fluorescent images of the four corners of the droplet wetting area on the substrate surface after droplet removal and drying, demonstrating successful deposition of material by dielectric charge injection (DCI)-facilitated electrowetting. The droplet contains 0.1 mg/ml of bovine serum albumin (BSA) conjugated with the fluorophore Alexa Fluor 488. Bright spots in the images indicate deposition of the fluorescent BSA onto the underlying surface.

Stage of Development:

- Proof of Concept

- Bench Prototype

Case ID:

21-9747_TpNCS

Web Published:

10/4/2024

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |